Large communities of surface-adhering microbes — also known as biofilms — have properties and can perform functions no single bacteria could on its own. Dental plaque, for example, is a naturally occurring biofilm that can wear down tooth enamel. Other biofilms can corrode steel.

But what if scientists could harness the pervasive power and resilience of biofilms and design them to perform specific tasks? It’s a novel concept BTI Director Claudia Schmidt-Dannert, in collaboration with University of Minnesota co-investigator Professor Alptekin Aksan, members of the Lawrence Livermore Lab, Georgia Tech and more, was recently funded nearly $2 million by the National Science Foundation to investigate. Her team’s goal? Design a bacterial system to extract critical minerals from mining or electronic waste products. This biomining technology could help meet the growing demand for valuable metals, but in a way that’s much more sustainable than conventional mining methods.

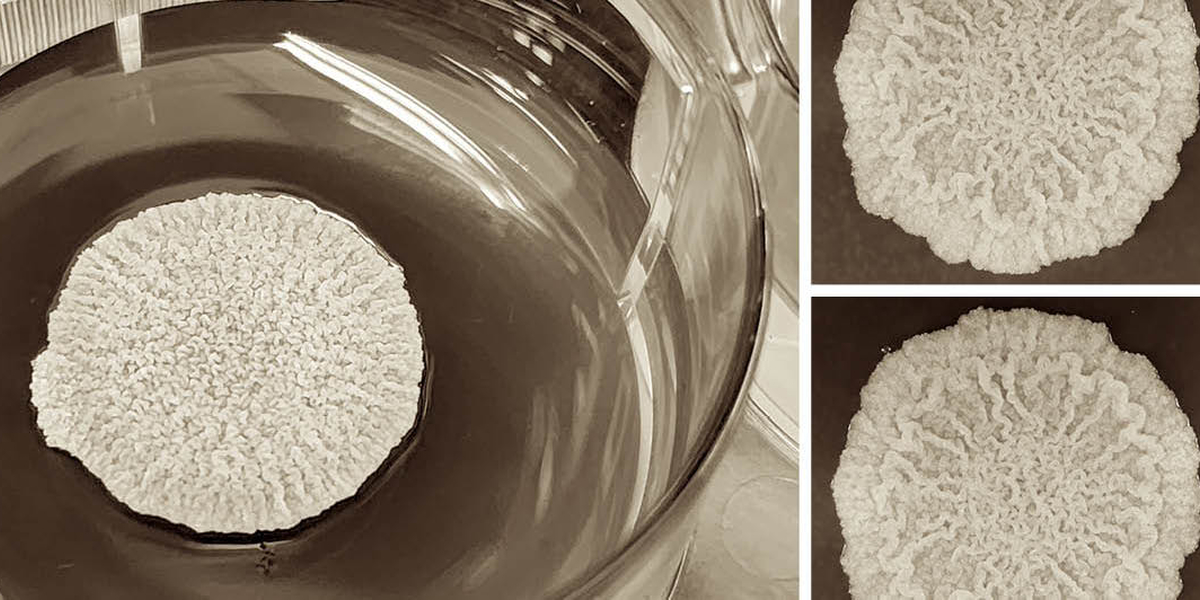

The foundational member for their innovative biofilm is a species called Bacillus subtilis, a safe, stable and fast-growing bacterium with a reputable industry history. With the addition of Deinococcus radiodurans — one of the most resilient microbes on the planet and known for its ability to bind metals — and a little tweaking, the two species could add up to a potent metal-binding bacterial “consortium.” The real battle is getting the two species to collaborate and perform targeted tasks.

“How do you get microbes that normally don’t coexist, to coexist and form a biofilm? And then make them do certain functions like metal precipitation and also interface with materials so that they build robust, functional biofilm materials that can be used in a real-world process application? No one has approached the new frontier of biological systems, really.”

B. subtilis and D. radiodurans don’t occur together naturally. But by adjusting the way they communicate or making them produce nutrients or other compounds the other needs, Schmidt-Dannert and her team can manipulate the two species to depend on each other.

Early research includes a lot of trial and error. On Schmidt-Dannert’s computer is a large photo gallery of perfectly plated bacterial colonies. Yellow, orange, smooth, ornate, wrinkly — and any combination of these — all from two species, but the trait differences are purely the result of small genetic modifications.

“Our first step is to set up the B. subtilis and see how we can intercept its regulatory network to make [and control] the biofilms that we want to make. We're going to over-express or control the expression levels of known key regulatory genes and investigate how this will change biofilm properties.”

By altering the growth medium and bio-engineering the genetic characteristics of both species, Schmidt-Dannert and her team will be able to manage the desired traits of their final biofilm products. Fast-growing, resilient, porous and strong — all of these traits make up a strong collective biofilm structure for mining and remediation applications. They will also engineer metal-binding proteins of the biofilm’s bacteria to target specific metals.

Sound complicated enough? Once they’ve jumped past the threshold of constructing the ideal biofilm “consortia” (a fancy term for the species composition of the biofilm), they have to figure out a way to implement them in a specially designed bioreactor. These bioreactors are comparable to the filtration systems of wastewater treatment plants, only, the filtration system is a bit more novel.

The biofilm is implemented by equipping the bioreactor with bacterium-infused silica-based mats. The fibers come pre-packed with essential nutrients, and the structure gives the bacteria a surface to grow on. The best part? The mat can be constructed by a 3D printer — nutrients, bacterium and all.

Acid is added to REE waste products in the bioreactor, which makes the metals readily available in an aqueous solution that’s pumped through the mats. As the solution flows through the mats, the bacteria acts like a filter and precipitates metal that will later “shed” from the bacteria as the final product.

“You can recycle the acid back into the tank for the next round, and then you regrow [the biofilm]. Biofilm waste is basically a biomass that's essentially organic material. And then you can use it for anything–you can use it for fertilizer or whatever you want to use it for.”

Though her team is only at the beginning stages, Schmidt-Dannert sees a future in which their technology is adapted for multiple earth-friendly outcomes. An important aspect of driving this development is also to engage with communities and stakeholders in Minnesota about biotechnology, efforts led by co-investigator Professor Elise Harrington in the University of Minnesota’s Hubert H. Humphrey School of Public Affairs.

“Our desired outcome is to learn how to design biofilms with the functions that we want them to have, and being robust and stable and safe. And then basically develop a platform that can then be ultimately used for many different applications — for capture of molecules, minerals and bioremediation.” – Adara Taylor